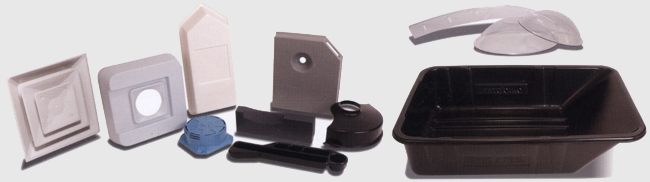

ROTATIONAL MOLDING & CUSTOM ROTATIONAL MOLDING

ROTATIONAL MOLDING BENEFITS

Whether it is for 10 parts or 10,000, rotational molding can offer the competitive advantage needed for your project to be realized. Rotational molding offers numerous benefits including economic tooling costs, uniform wall thickness, quick turnaround and reasonable piece price.

The rotational molding process is ideal for:

- Hollow parts

- Foam-filled parts

- Double-walled parts

- Parts where strength is critical

ROTATIONAL MOLDING MATERIALS

Materials plastics, polymers and coatings that can be used for Rotational Molding include:

- Plastisol (PVC)

- Polyethylene (PE)

- Nylon

- Polypropylene (PP)

- Polyurethane (PU)

- Ethylene Vinyl Acetate (EVA)

CUSTOM ROTATIONAL MOLDING

Expert Roto also offers custom rotational molding for most any project.

Call Customer Service at : 513-735-1400

THERMOFORMING

THERMOFORMING OPERATIONS

Expert Roto offers custom thermoforming and part finishing for plastic part manufacturing, prototyping, and plastic part fabrication. Custom thermoforming plastics, pressure forming plastics and vacuum forming plastics processes are available. From limited quantities to large runs, we can meet all of your thermoforming needs up to a 10’ x 6’ part. We specialize in thick gauge plastic parts and value added secondary operations. With ISO 9001:2008 certification, four thermoforming machines, and (4) 5-axis CNC trim tables, we are the perfect fit for all of your thermoforming needs.

THERMOFORMING PROCESSES

We offer custom thermoforming, pressure forming and vacuum forming production and finishing for:

- Thick-gauge plastic parts

- Enclosures

- Plastic part manufacturing / fabrication

- Prototype part manufacturing

- Short-run plastic part manufacturing

- Plastic part finishing

THERMOFORMING INDUSTRIES & APPLICATIONS

Thermoforming industries and applications include a broad range of OEM companies from automotive to waste management. With a wide variety of materials to choose from we can meet your specifications and requirements, every time. From product design to tooling, consistent molding, and precision CNC trimming operations – Expert Roto stands out when quality products at a reasonable cost are required.

Some common thermoforming industries and applications are:

- Disposable food packaging

- Consumer goods packaging

- Computer, industrial, and medical

- Aerospace, automotive, and marine

NEW PRODUCT DEVELOPMENT

Call Customer Service at : 513-735-1400